Batch dryers

COLUMN MINIDRYER

THE DRYING COLUMN consists of an upper loading hopper, a number of modules with rounded ducts inside immersed in the cereal, a discharge hopper and a vertical auger (optional bucket elevator) which deal with loading, recirculation and discharge, and a hot air production unit.

The cereal drops down by gravity in a zigzag movement and is hit by a flow of hot dry air in counter-current which crosses the ducts and the cereal; the saturated air flow is dispersed in the atmosphere.

The quantity of cereal at the outlet is predetermined and regulated by an electrically motorized extractor.

The product collected in a hopper drops into a vertical auger (optional bucket elevator) which feeds the drying column as many times as necessary to reach the desired final humidity (recycle).

At the end of the drying, the cereal is cooled and sent to the outlet by means of a two-way valve installed on the recirculation auger (optional bucket elevator).

The hot air generation unit consists of: a two-stage burner controlled by thermoregulators, a stainless steel oven (optional heat exchanger), a fan and a duct for connection to the drying column.

.

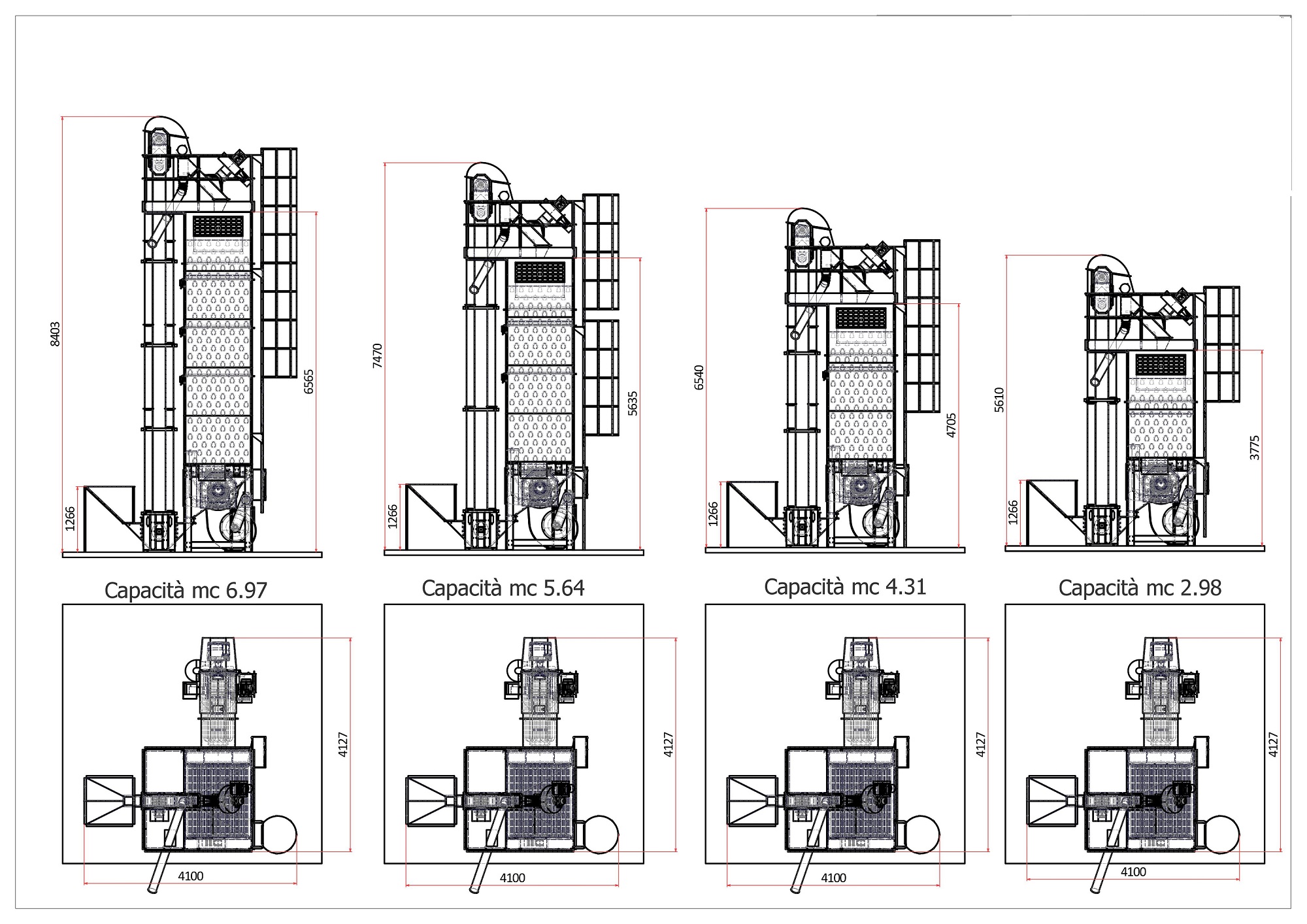

| Model | Capacity mc | Electic Motor kw |

Width mm C |

Length mm D |

Height mm B | Overall height mm A |

| ES30LD | 3 | 6 | 4.100 | 4.127 | 3.775 | 5.610 |

| ES40LD | 4,5 | 7 | 4.100 | 4.127 | 4.705 | 6.540 |

| ES50LD | 5,7 | 8 | 4.100 | 4.127 | 5.635 | 7.470 |

| ES70LD | 7 | 10 | 4.100 | 4.127 | 6.565 | 8.403 |